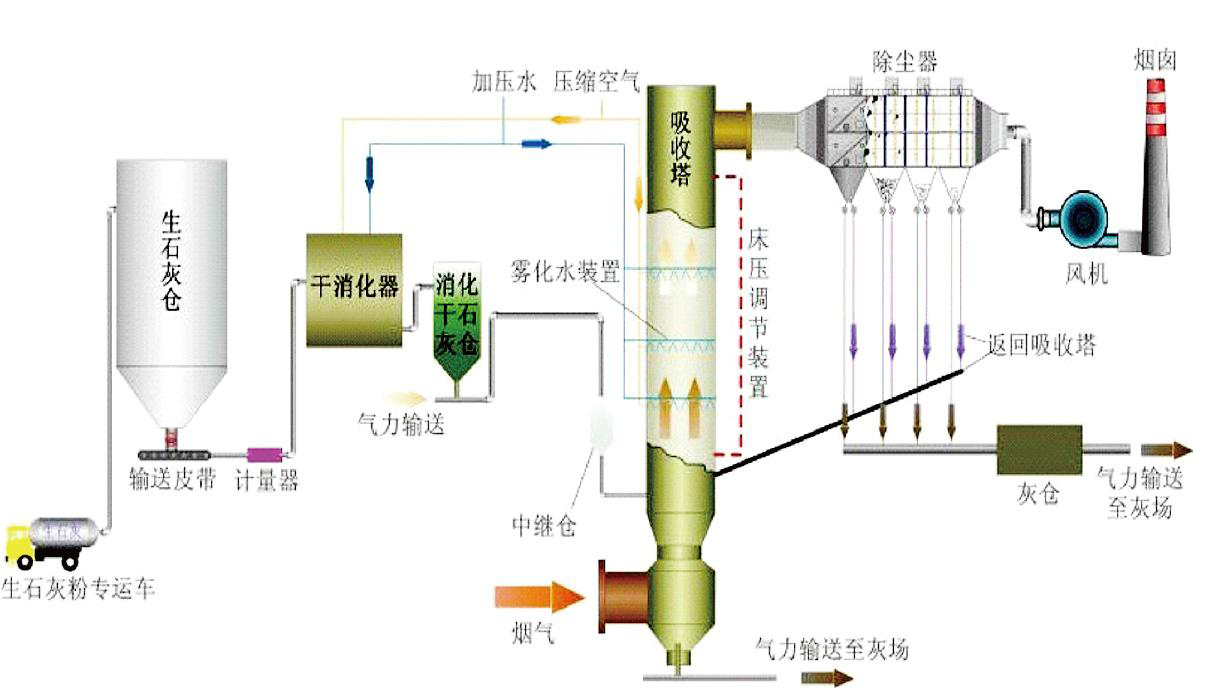

1. Principle of flue gas circulating fluidized bed desulphurization

CFB process is used to install fluidization tower between air preheater and dust collector. The bottom of the flue gas tower enters and contacts with the lime powder and the humidifying water. The flue gas velocity in the tower is designed in the high relative velocity of solid / gas two-phase, and the material layer is suspended. The flue gas SO2 is absorbed by the slaked lime to produce calcium sulfite. In addition, new surfaces are constantly involved in the reaction. The particles taken out of the tower by the flue gas are collected by the subsequent dust collector and reflow to the absorber for reactivity.

Two. Characteristics of flue gas circulating fluidized bed desulphurization

(1) small area, save land resources;

(2) desulfurization and dust removal efficiency is high, one step in place, to meet the long-term environmental protection standards of the country:

The SO2 emission concentration is less than 100mg/Nm3 and the dust emission is less than 30mg/Nm3.

(3) the system is simple, the auxiliary system is small, the operation is reliable and the operation is simple.

(4) no waste water discharged and no two pollution.

(5) raw materials can be supplied stably with waste alkali liquor and cheap lime.

(6) the product is dry and can be used in a comprehensive way.

(7) the transformation project can be implemented step by step according to each furnace, and the transformation will not affect the normal production of the thermal power plant.

(8) the safety and stability of the system operation