The desulfurization spray tower is a tower type equipment for desulfurizing waste gas. The desulphurization tower is the most widely used in granite masonry at the beginning, and it can prepare different desulfurizing agents and achieve the effect of dust removal and desulphurization at the same time. It is suitable for flue gas desulfurization of coal-fired industrial boilers and kilns. In the desulfurization tower, SO2 containing flue gas should be used for chemical absorption of SO2 in the flue gas. In order to strengthen the absorption process, improve the desulfurization efficiency and reduce the investment and operation cost of the equipment.

Two. Structure of desulphurization spray tower

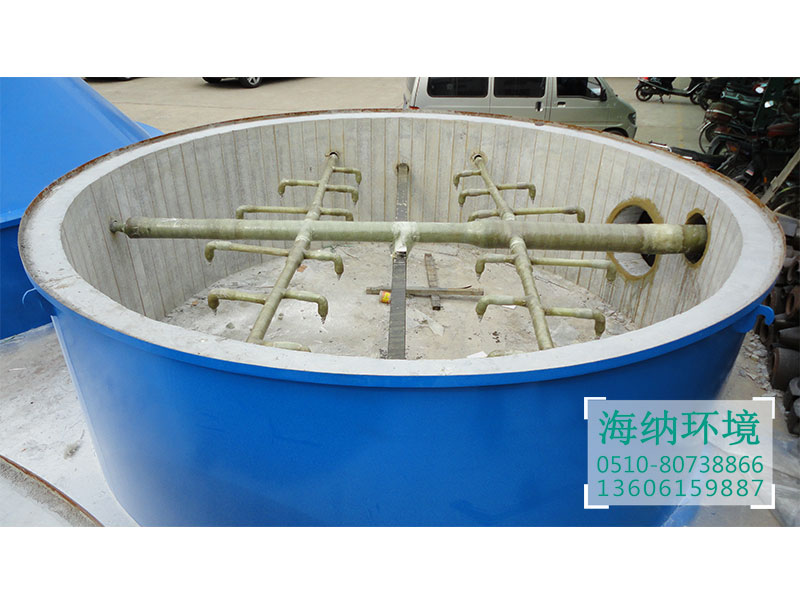

The desulphurization spray tower is particularly important for internal corrosion protection. It determines the stability and service life of the equipment. It can be lined with scale resin. The interior of the desulfurization spray tower of our company is used as a heavy anticorrosion structure. It has high corrosion resistance, temperature resistance, wear resistance and high bonding properties.

The desulphurization tower is sprayed with air tower, and the spray spray layer of FRP is used in the inner spray layer of the tower. The spray cover of the tower can reach more than 250%, which improves the contact between the flue gas and the slurry, and promotes the absorption of the sulphide by the alkali solution.

The top is made of two layer baffle demister, which effectively dehydrated and fogs the flue gas after desulphurization, and the purified flue gas is discharged to the atmosphere through the chimney. The mist eliminator sets a regular backwashing device to avoid the crystal and ash of the demister plate. The backwash can be washed by the time set by the plant area process water (or tap water).

The desulphurization spray tower is suitable for production. It can be manufactured according to customer needs. It can be manufactured as a whole and can be divided into modules.

Three. Characteristics of desulphurization spray tower

(1) there is a larger contact area between gas and liquid and a certain contact time.

(2) disturbance between gas and liquid is strong, absorption resistance is small, and absorption efficiency of SO2 is high.

(3) stable operation and proper operation flexibility.

(4) the pressure drop is small when the air flow passes.

(5) simple structure, easy manufacture and maintenance, low cost and long service life.

(6) no scaling, no clogging, wear resistance and corrosion resistance;

(7) good resistance to temperature and wear resistance;

Four, sodium alkali desulphurization process

The sodium alkali method uses the solution of Na2CO3 or NaOH as the absorption liquid to absorb and purify the SO2 and some dust in the flue gas. The waste liquid after the purification is flowing into the circulating pool for precipitation and the desulfurizer is added back to the absorption tower.

Process principle:

1. Absorption reaction

SO2 dissolves SO2 (gas) - SO2 (liquid)

SO2 (liquid) +H2O===HSO3-+H+

HSO3-===H++SO32-

2NaOH+SO2===Na2SO3+H2O

Na2CO3+SO2===Na2SO3+CO2

Na2SO3+SO2+H2O===2NaHSO3

In this process, sodium base is used as absorbent, so no precipitate will be generated in the absorption system. The main side reaction is oxidation reaction, which generates Na2SO4:

2NaHSO3+O2===2Na2SO4