The ceramic multi tube deduster is a cyclone dust collector, which is suitable for chain furnace, circulating fluidized bed boiler, hot water boiler, biomass boiler, reciprocating furnace, boiling furnace, coal puler furnace, coal water slurry furnace, sintering machine, hot blast stove, lime kiln, rotary kiln and other types of industrial boilers and power plant boilers with different combustion formulas.

The use and characteristics of equipment

1, for other industrial dust, it can also be treated with this dust collector, such as cement, lime powder and other valuable dust.

2, processing air volume, load adaptability, ceramic core smooth and durable, will not cause blockage.

3. The floor area is small. It can be installed flexibly according to the user's condition, and can be placed indoors or in the open air.

4, the exit is opposite to the outlet, the side outlet, the top outlet, convenient flue connection.

5, generally no brake parts, convenient management, simple maintenance, no additional costs.

6. The box is made of carbon steel, and the non flange interfaces are all continuous welded. The overall leakage rate is less than 3%.

7. The lower dust collecting box angle is designed according to the dust rest angle, and the angle is generally 55~65 degrees to prevent ash accumulation inside the ash hopper.

8, the ash unloading valve adopts manual ash removal device, or the electric ash discharge valve with excellent sealing performance can also be used.

9, the one-time investment is less; compared with the electrostatic precipitator, the total investment is less. Compared with the water film type dust collector, there is no circulation water, no two pollution, no wastewater discharge, and no water treatment equipment is needed.

Two. The principle of dust removal

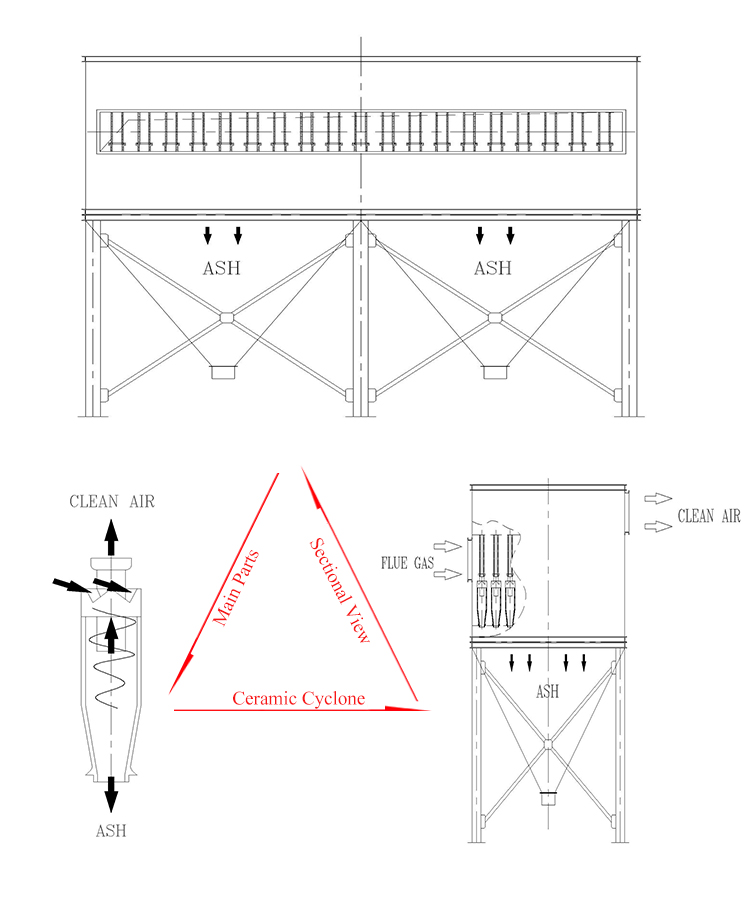

The ceramic multi tube dust remover adopts ceramic cyclone arrangement. The cyclone consists of a guide, a separating cylinder and an exhaust pipe, and is made of high quality ceramic material.

When the dust gas enters the inlet of the dust collector, the dust and the gas are separated by the ceramic guide, the dust and the gas are separated under the action of centrifugal force. The dust falls in the dust collection box, the dust is discharged by the discharging valve, and the dust which can be used two times is recovered. The gas is formed to form the updraft after the purification, and concentrates the exhaust pipe to the exhaust pipe. The collection chamber is discharged from the equipment outlet to achieve the dust removal effect.

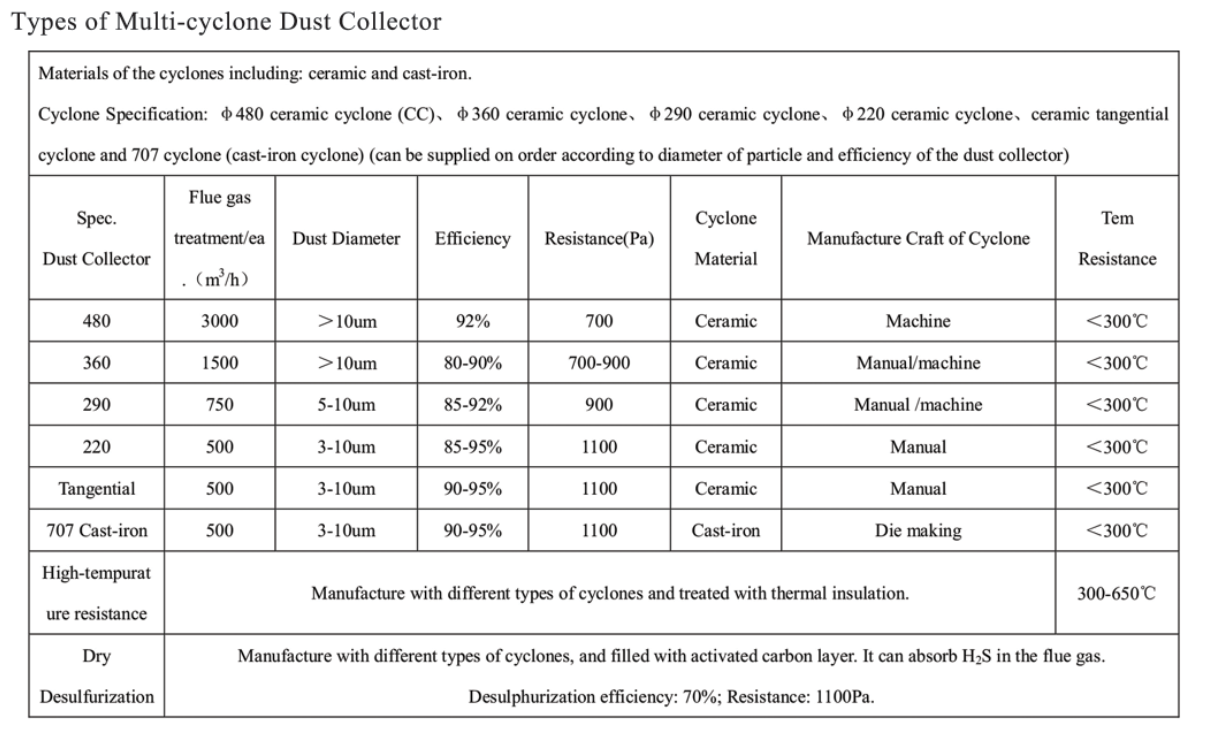

Three, each kind of dust collector picture, with the corresponding whirlwind and technical parameters.

1. The dust removal efficiency of particle size above 10 m is 80-90%.

2, equipment resistance: 700-900Pa;

3. The blackness of Lin: 0~1;

Four, equipment selection

Calculation of the quantity of cyclone needed in the dust collector

N=Q/C,

N - the number of whirlwind (Branch):

Q - flue gas quantity (m3/h) required to be treated

C - cyclone single pipe to deal with the amount of smoke, (m3/h/ branch)

The size of the box is redesigned under the premise of satisfying the dust removal effect, and according to the security space, transportation conditions and installation conditions.

Transportation out of the factory:

|  |

|  |